Epoxy flooring can be applied in a variety of different areas. Some common places are garages, workshops, warehouses, factories, or any other place where there is constant foot traffic and the need to protect the concrete surface from chemicals or physical damage.

There are many different types of epoxy coatings that you can apply to your concrete surface. Each type of epoxy has its own advantage for specific installation areas. This article will look at what epoxy actually is, the different types of epoxy coatings, and the most common areas you will find epoxy floors.

What is an Epoxy Coating?

An epoxy coating is a chemical reaction with active chemicals that harden. It leaves a protective layer on the surface it has been applied to. Epoxy is available in many different forms, including paints and floor coatings. These surfaces are very durable, chemical resistant, and easy to clean.

Epoxy coatings are ideal for heavy traffic areas where there is a high chance of chemicals spilling or coming into contact with the concrete surface. Some common areas include garages, workshops, warehouses, or factories that handle large quantities of chemicals.

Types of Epoxy Coating

Different epoxy coatings are available, depending on their intended use. The two most popular epoxies for flooring are Polyaspartic and Urethane. They are both made up of polymers but have different combinations of hardeners that make them suitable for specific applications.

Polyurethane Epoxy Flooring

These types of epoxy flooring have a higher number of crosslinks which make it harder and more durable. It is important to note that Polyurethane epoxy flooring will emit some sort of odor when applied. Typically, it takes around 48 hours for the smell to dissipate.

Polyaspartic Epoxy Flooring

Polyaspartic epoxy hardens with exposure to air, making it ideal for areas with no moisture or humidity in the air (example: warehouses). This type of epoxy flooring does not have an odor so that it can be used indoors. However, due to their chemical makeup, Polyaspartic epoxies are easily damaged compared with other types of epoxy used for garage floors.

Self-Leveling Epoxy Flooring

Another type of epoxy flooring is a self-leveling coating. This type of epoxy is very thin and typically used as a leveling layer underneath another thicker form of epoxy. It’s important to note that their chemical makeup makes them water sensitive, which means you need to keep the humidity low during the application and drying process.

Metallic Epoxy Flooring

There are also metallic epoxies that have metal flakes mixed into the chemical combination. These types of epoxy flooring come in a variety of colors and finishes, making them perfect for aesthetic purposes as well as durability.

Flake Epoxy Flooring

Flake epoxy is very similar to Metallic epoxies, but it has a higher concentration of metal flakes. This type of epoxy flooring will have a more consistent color throughout the coating compared with Metallic Epoxy Flooring.

Common Areas for Epoxy Coating

If you are looking to install an epoxy floor in your home, there are different types of installations depending on where you want to use it. Garages and workshops typically need strong durability against chemicals or physical damage, while the basement might need waterproofing due to humidity concerns.

Garage Epoxy Flooring

Some common places that garages require epoxies are their floors, walls, or both if they are exposed concrete. Garage floors must be able to withstand spills and harsh chemicals to keep them functional.

Workshop Epoxy Flooring

Epoxies are commonly used for workshop areas as well, but they need to be more durable than garages because of the amount of traffic and chemicals coming in contact with them.

Basement Epoxy Flooring

Basements can also benefit from an epoxy floor if they have concrete floors. This is due to high humidity levels making concrete surfaces susceptible to mold growth or water damage.

Commercial Epoxy Flooring

Another common application for epoxy coatings is in commercial areas. This includes kitchens, restaurants, or other businesses that handle chemicals or produce large amounts of moisture.

Manufacturing Areas

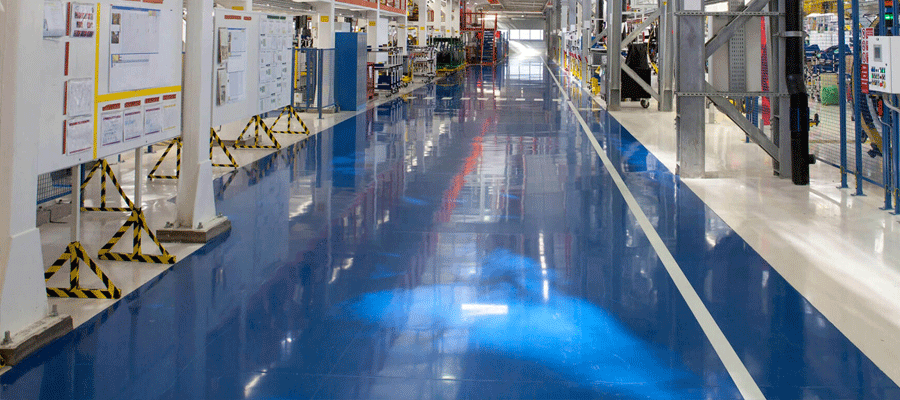

Epoxies are commonly used in manufacturing plants due to their protective nature against oils and acid spills. They are also easy to clean, making them ideal for these types of environments where food handling is involved.

Retail Stores

Epoxies also work great in areas such as retail stores, warehouses, and garages since they can be used to mark out spaces for items. They are good for guiding forklifts and other vehicles while driving indoors or on asphalt or cement surfaces.

Application Areas

There are many different ways that epoxies can be applied depending on the material it’s being applied over and how rough the surface is. The three most common ways of applying epoxy flooring are: by hand using a squeegee, with a paint roller, or through a sprayer. Each method has its pros and cons, which will vary from project to project. For example, using a sprayer usually requires more training to operate safely, but it applies the coating quickly and evenly.

Manufacturing Facilities

Commercial businesses such as manufacturing plants often need a way to contain spills of harmful chemicals, even if they only occur once every few months. Since epoxy coatings are waterproof, they can absorb the spilled liquid before it seeps into concrete surfaces. If these chemicals happen to soak through the epoxy coating, there is no fear of corrosion or rust since epoxies do not rust or corrode easily.

Warehouses

Warehouse environments also benefit from using epoxy flooring over concrete surfaces because many items that are stored on racks can form static electricity, which leads to an explosion risk when mixed with gasoline and other chemicals. This is due to the buildup of static electricity between floor tiles or coating surfaces that can attract gasoline or other flammable liquids.

Hospitals

Epoxy floors are also common in hospitals due to their anti-slip properties as well as the high chemical resistance since most cleaning chemicals used on surfaces such as floors and walls can be harsh. These chemicals include bleach, isopropyl alcohol, or even solvents. This makes epoxy coatings a sensible choice for flooring materials in this type of medical setting.

Professional Kitchens

Professional kitchens in restaurants often have to deal with large amounts of grease, oil, and other liquids that are spilled accidentally. Epoxy coatings are great because they help control the amount of water penetrating into concrete or stone surfaces while still being able to handle kitchen grease, which is common when cooking.

Auto Showroom

Auto showrooms also benefit from using epoxy coatings over the floor because of the amount of traffic caused by customers looking at and walking around new or used cars. Epoxy surfaces are often preferred for this application due to their commercial-grade strength and ability to resist abuse like oil, dirt, and grease.

As you can see, epoxies are great choices for various applications in commercial spaces. Not only do they provide a high-performance environment by protecting concrete or stone surfaces, but they also offer value in terms of minimizing time spent on routine maintenance and floor refinishing.

If you need more information on epoxy flooring installation in Austin, reach out to our team of experts at Epoxy Flooring Austin. We have been in the flooring industry for many years and have installed epoxy coatings all around Central Texas.