Warehouses require a lot of upkeep. Because warehouses are used for storage, they’re susceptible to damage from dust, chemicals, and other elements that can hinder the quality of the environment. Warehouse floors often need to be cleaned frequently and may even be exposed to corrosive substances, oil stains, or other contaminants that degrade the floor’s durability.

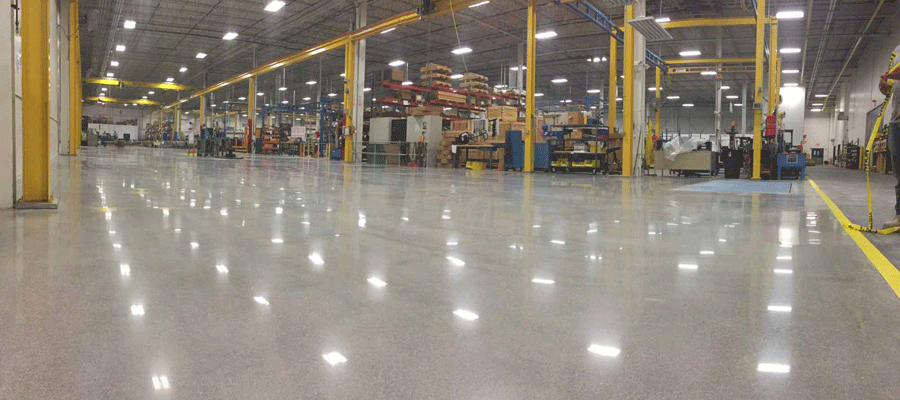

Epoxy coatings have been identified as an ideal surface coating for warehouse floors due to their exceptional qualities: toughness against abrasions and chemicals, resistance to peeling or blistering from rust or corrosion, an extended lifespan with little maintenance needed to preserve them under harsh conditions. In addition to being tough enough for warehousing purposes, epoxies also offer attractive appearance options such as custom colors and decorative effects.

Why is Warehouse Epoxy so Durable?

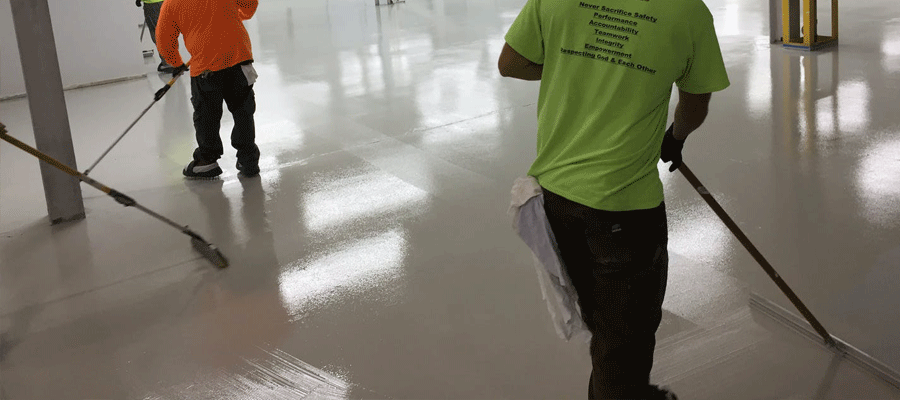

Epoxy is extremely durable due to the way it bonds with most surfaces. Because epoxy adheres tightly to its surface, it forms a protective layer that resists harsh chemicals and abrasions and maintains a firm grip on the substrate it has been applied to.

Epoxy floor coatings also have excellent chemical resistance properties, which means that they won’t be affected by spills or even corrosion from salt or other materials commonly found in warehouses. Without proper protection (epoxy), floors exposed to such elements can corrode and become weakened over time until structural integrity is compromised. If bare concrete would be used as a flooring material for warehouses, for example, warehouse epoxy would need to be applied because of the possibility of degradation from corrosive substances like salt.

What are the Benefits of Epoxy Coatings in Warehouses?

Warehouses are places where tough conditions can arise at any time, leading to damaged flooring that needs to be fixed or even replaced. With warehouse epoxy applications, cleaning and maintenance become much easier because floors now have protective properties which resist corrosive materials and chemicals. Warehouse epoxies also offer higher impact resistance than most other types of polymer coatings, so warehouses with heavy foot traffic can use them without worrying about wear and tear on the coating surface.

Some additional benefits of warehouse epoxy flooring include:

– The ease of cleanup after accidents or spills

– Thicker coats create more durable surfaces

– Epoxy flooring is slip-resistant, aiding in safety

What are the Different Areas that Warehouse Epoxies are Used for?

Warehouse epoxy coatings can be used anywhere in warehouses where toughness and durability are needed to keep the surface in good condition. They’re commonly used on floors, but warehouse epoxy can also be applied to walls, even if they’re not being used as loading zones. Decorative effects may be added to the coating depending on user preference.

Warehouses with heavy foot traffic benefit from having their walls painted with chipped paint effect or other designs because it makes the area easier to navigate for employees. Other common areas that warehouse epoxy is applied to include:

– Loading zones where forklifts and other machinery are used for transportation

– Under stairs and around posts so they won’t be scuffed by moving equipment or supplies

– Around electrical panels, plumbing, and other utility areas where moisture will be present

What Other Types of Coatings Can Be Used as Alternatives?

Industrial floor coatings come in a wide range of varieties, each with its own benefits. Choosing the right coating for a warehouse depends mainly on what the primary use of the area will be. A typical warehouse doesn’t just place items on shelves and leave them there until they’re sold; it receives deliveries and ships out new shipments on a regular basis. Because warehouses are so busy, they need flooring material that can withstand heavy foot traffic.

Epoxy resin coatings are reliable choices for warehouses with this type of traffic because the protective layer created by the coating is resilient against chemicals and abrasions. Epoxy also offers attractive options such as decorative effects like chipped paint or decorative stones that can be added to further enhance safety in areas with heavy foot traffic. Some other types of warehouse flooring materials include rubber tiles, ceramic tiles, epoxy-coated steel sheets, cork boards, asphalt sheeting, and more.

What Are the Maintenance Requirements for Warehouse Epoxy Coatings?

Because epoxies create a protective layer on top of most surfaces they’re applied to, it’s important to ensure that the material remains clean and free of dirt and debris. This can be accomplished by using a regular sweeping/vacuuming routine to pick up loose materials, scrubbing with hot water and soap to remove stains, or applying an acid wash to remove rust or other stubborn substances. Although warehouse epoxy floor coatings don’t require the frequent waxing and polishing that carpets do, users should still periodically check their floors for residue; if necessary, they can use diluted vinegar to remove these spots before reapplying more floor coating where needed.

Warehouses often deal with dangerous corrosives and chemicals, making it important that epoxy surfaces are cleaned regularly. This is so accidents won’t lead to hazardous situations where employees could get injured. Not only does this protect workers, but it also protects the company if someone slips and gets hurt on warehouse flooring that’s not up to standard.

As discussed earlier, many warehouses deal with large machinery like forklifts, which can cause chips and scuffs in coating material if they’re not treated regularly. Depending on how frequently forklifts move about an area, this could happen anywhere from monthly to even daily; no matter what the setup is for a warehouse facility where forklift traffic is present, it’s very important to make sure these machines are clean after each use.

Epoxy coatings are designed specifically for heavy-duty industrial areas, making them one of the most reliable materials available when choosing an industrial flooring option. When applied properly, warehouse epoxy coatings can provide years of durable service.

Warehouse epoxy floor coatings are a popular choice for companies that need industrial flooring in an area where pedestrian and forklift traffic occurs frequently. The protective layer created by warehouse epoxy is resilient, but it’s also resistant to chemicals and abrasions; this means that the area will look beautiful and remain safe for employees who work there over time. Warehouse epoxy coatings can be applied either thick or thin depending on what type of effect the user wants; when used correctly, they also provide years of reliable service.

If you are ready to install some warehouse epoxy floor coating, please reach out to us at Epoxy Flooring Austin for more information! We are located in Austin, Texas, and serve the surrounding communities.